Consultancy & Design

AMMA provide consultancy services for all aspects of additive manufacturing and 3D printing. We assess existing capabilities & processes and advise where additive manufacturing can help your organisation.

We provide standard and tailored assessments depending on your requirements. Our services include specific recommendations for hardware and software, as well as more generalised advice regarding 3D printing.

Some of the consultancy services we offer:

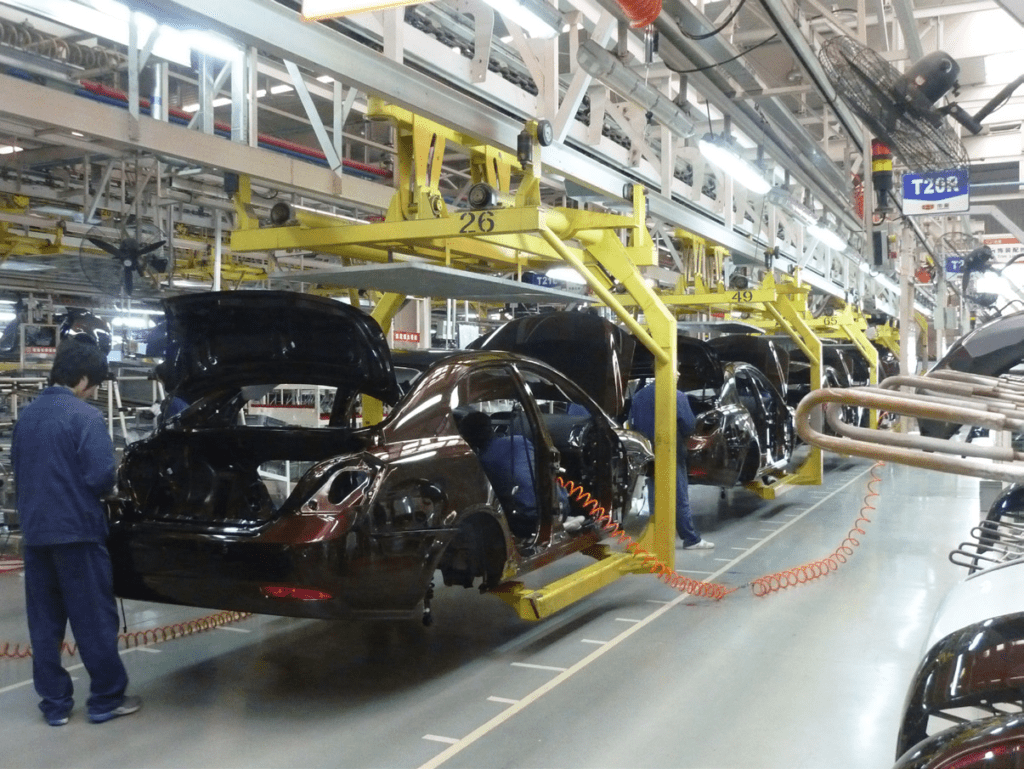

Factory-floor Assessment

This involves observing and documenting the current processes as they exist on the factory floor or production line, allowing us to provide detailed analysis on the suitability of 3D printing for your production areas. Often we find huge value comes from introducing 3D printing to the supporting operations for production facilities, usually in the form of reduced downtime and quicker response to changing needs. Additionally, aides for manual production can be manufactured and continually refined with an ease not possible before, unlocking new levels of efficiency and worker comfort.

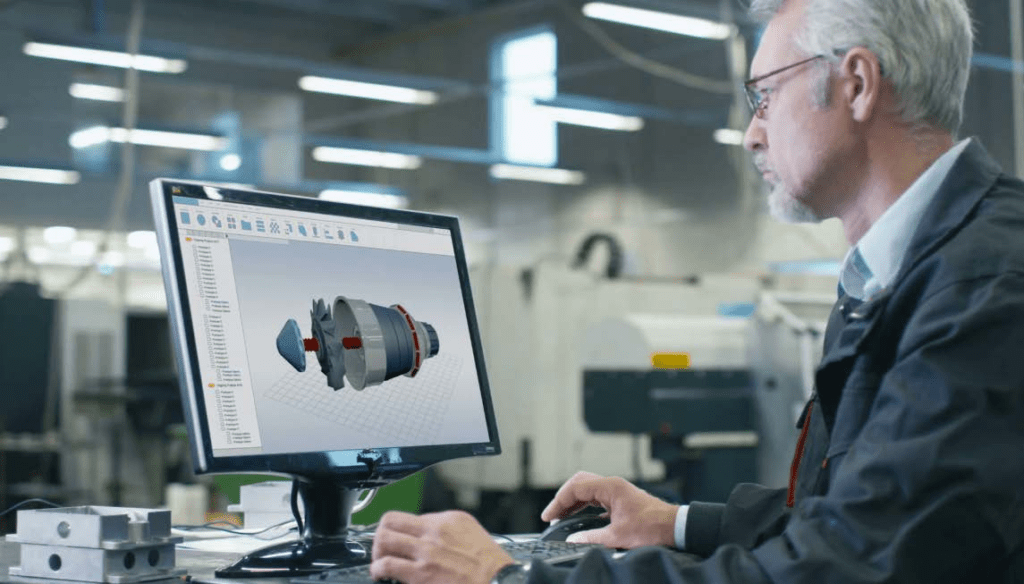

Process & Work-flow Assessment

Similar to the Factory-floor assessment but focusing on the actual processes and workflows involved. We can look at your new product introduction ‘NPI’ and similar design methodologies to advise where 3D printing could help. Integration of additive manufacturing at the heart ofR&D strategies can equip an organisation with the agility and flexibility to remain competitive and responsive to customers’ ever growing expectations.

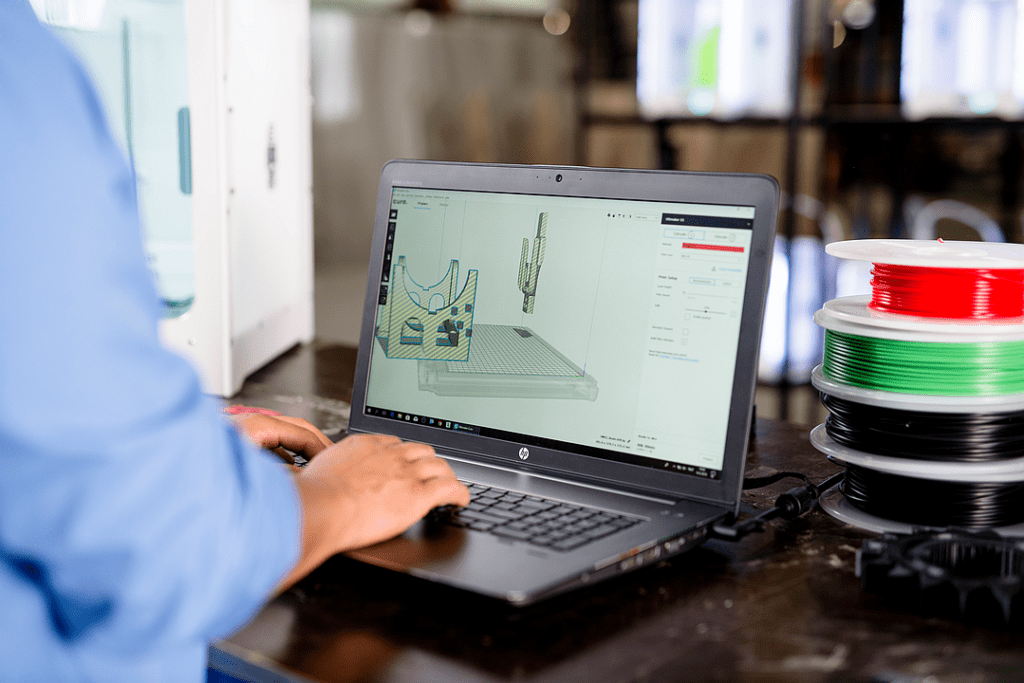

Printing Technology, Printer, and Material Selection Advice & Guidance

There are many different additive manufacturing technologies that can all be considered “3D Printing” – FDM, CFF, SLA, SLS, EBM… the list goes on. There is a wide range of brands that each have their own strengths and advantages, depending on individual requirements. In addition to the machines themselves there is a myriad of different materials, each with specific properties and intended uses. AMMA can advise and recommended on all aspects of selecting an additive manufacturing approach tailored to your specific needs, requirements and constraints.

Design for Additive Manufacturing “DfAM”

The best returns are experienced by organisations that fully embrace additive manufacturing – key to this is adapting design and manufacturing processes to exploit new possibilities. Using “Design for Additive Manufacture” principles, companies can transform their design and production endeavours for the better. From simplification and consolidation of multi-part assemblies into single-piece units, to massive reductions in QA and related operations, all contribute to greater efficiencies and quicker responsiveness. The AMMA team have extensive engineering experience across many sectors and industries enabling us to carry out detailed analysis of exactly how and where to focus efforts for the best returns.