Rapid Prototyping

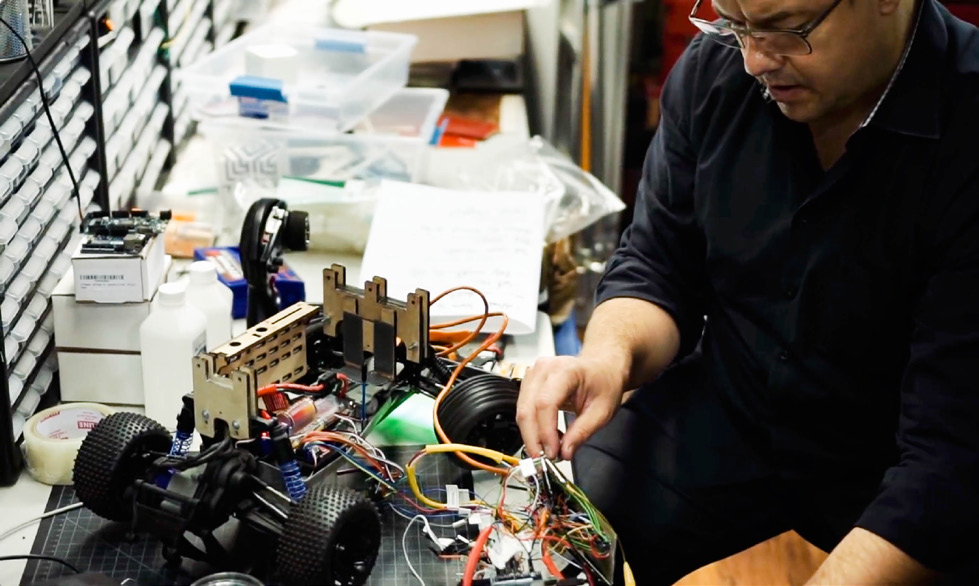

Rapid prototyping describes techniques used to fabricate scale models or physical components and assemblies quickly, using 3D CAD data which is then input to a 3D printer. The parts that are output from the 3D printer allow users to:

- Test form and fit with highly accurate models

- Validate design ideas without having to invest in tooling

- Refine products quickly before moving to full production by iterating more freely

- Carry out functional testing to gauge performance of a design during the development stages

- Keep intellectual property in-house

- Communicate ideas internally more effectively with tangible objects

Additive manufacturing is an extremely effective way to communicate ideas between teams, whether it be designers, engineers, product managers or finance directors. The ability to hold physical models in your hands in hours or days rather than weeks is a huge advantage for any development company.

One of the most commonly used approaches for justifying the use of additive manufacturing is to calculate what the savings are when compared to using traditional manufacturing methods for producing prototypes. AMMA Solutions provide a 3D printing service as well as sales, installation & training for the machines themselves to enable customers to take advantage of these savings.

Every business has different needs when it comes to rapid prototyping. Whether you’ve already got an in-house 3D printer, are considering investing in one, have used a 3D printing service in the past, or are simply interested in learning more about additive manufacturing, don’t hesitate to get in touch using our contact form.

- Bring products to market faster

- Quickly and easily iterate designs

- Assess manufacturability

- Test functionality