Engineering

Additive manufacturing is becoming more and more commonplace within engineering environments with clear benefits such as shorter development times, faster routes to market and the ability to create multiple iterations for validation before investing in expensive tooling. Specially designed mounts, holders and guides can be produced quickly and easily for testing of components and sub-assemblies. Engineers can create parts with complex internal structures and geometries that would have been incredibly difficult, if not impossible with traditional manufacturing methods.

Selection of 3D printing use-cases in Engineering

Concept Models

Moving from digital CAD models to physical, printed parts rapidly accelerates product development and reduces costs. Printed parts are hugely effective at communicating design intent allowing for better decisions to be made more quickly. Concept models can be created that both look and feel like finished products with smooth surface finishes and fine details. A range of materials can be used to form multi-body assemblies including soft-touch buttons, flexible rubber seals and clear components.

Functional Testing

3D printing materials are now available with the engineering properties required to withstand full functional testing. Whether your application requires high impact strength, low volatility, increased temperature/chemical resistance, there are options available for engineers across the board. The introduction of composite printed parts integrating carbon fibre, Kevlar and fibreglass opens a whole new realm of functional, end-use parts that can be produced using additive manufacturing. These printed plastic parts have mechanical properties comparable to, and in some cases outperforming, those of metals such as Aluminium.

Custom Tools & Parts

Bespoke parts and custom tools for specific applications can be created quickly and cheaply. Instead of taking up time on a machining centre, 3D printers can be used to create the non-value-added parts ensuring high repeatability with the mechanical properties required for the job. Soft jaw inserts can be designed and produced to match the exact geometry of the workpiece to securely hold parts without marring or damaging soft metals and plastics. The high speed and low cost of raw material makes 3D printing an ideal solution for drill guides, marking templates and surrogate parts.

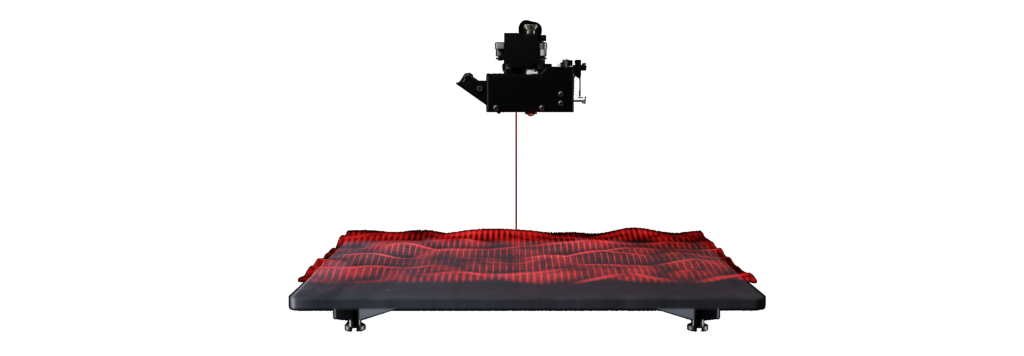

Jigs, Fixtures & Gauges

Many engineering and manufacturing applications make use of jigs and fixtures to simplify processes, making them more reliable while reducing cycle times and improving worker safety. Traditionally these parts would be machined in metal, either in-house or by outsourced machining companies. Depending on the specific application these parts don’t necessarily need to be produced in metal. With the development of 3D printing materials to include high strength composites – jigs, fixtures and gauges can now be printed to replace metal fittings on assembly lines, in automated machining operations, casting foundries, and production facilities around the world.

Small Production Runs

Not only can parts be printed directly in low volumes for small production runs, injection moulds and machining/casting tooling can also be produced to minimise up-front costs caused by design iterations early on. The process for creating a tool using 3D printing is much simpler than with traditional methods which typically involve multiple processing steps, each requiring a machinist. Additive manufacturing tooling fabrication uses a 3D slicing software to convert CAD models directly to a 3D printable file. This negates any requirement for a technician to read and interpret manufacturing drawing packs and speeds up the process.