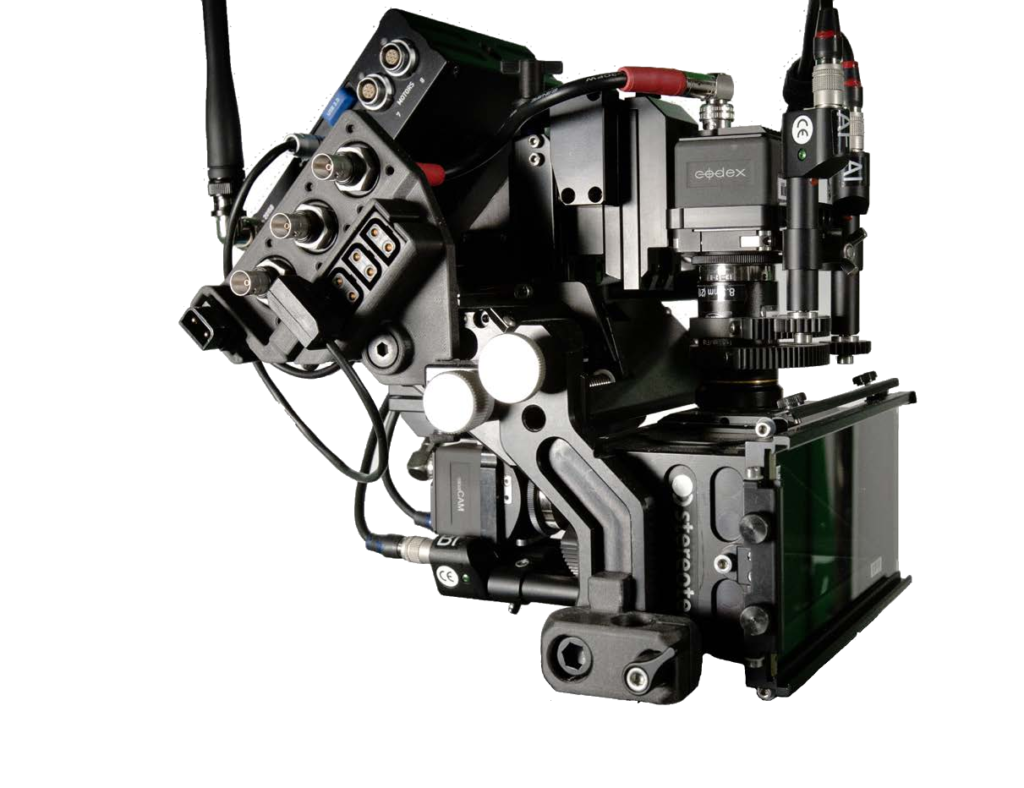

Production Parts

Additive manufacturing is becoming more and more commonly used to fabricate production, end-use parts in low volumes – with runs up to around 1000 units. 3D printing doesn’t require tooling and can produce complex production parts in low volumes faster and more cost effectively than when using traditional methods.

If there are design changes required during a production run there is no need to alter or create new tooling, the new design is simply uploaded to the printer(s) and the changes are reflected in the next production run. The ability to create complex internal features in the same robust thermoplastic and metal materials that were available with traditional manufacturing has enabled 3D printing to transcend its use in prototyping to an effective production method.

In order to fulfil the requirements for end-use applications, 3D printing materials must have certain mechanical, chemical and even biocompatible properties. The development of printing materials in recent years has enabled additive manufacturing to produce parts with a variety of specialist properties, including:

- Aerospace flammability ratings

- UV and Chemical Resistance

- Conductive Filaments

- ESD Materials

- Bio-compatible Materials for implantation

- Food-safe compatibility

Companies such as General Electric, Airbus and SpaceX are using industrial 3D printing technology to produce functional, end-use parts including fuel nozzles, mounts, cabin brackets and engine chambers. The flexibility offered by additive manufacturing combined with engineering-grade materials make it a viable option for a wide range of low volume production requirements. Parts can be modified to meet customer demand and can be brought to market more quickly using 3D printing.